Pleats are more than just folds in fabric. They are the architecture of movement in fashion design. Whether creating volume in a skirt or adding structural elegance to a bodice, a well-executed pleated dress balances aesthetic beauty with technical precision. However, for emerging brands and designers, pleats represent a significant manufacturing challenge: they are easy to sketch but difficult to execute consistently in production.

This guide explores the essential types of pleats, the industrial pleating process, and how to partner with the right manufacturer to bring your vision to life.

8 Essential Types of Pleats in Modern Dressmaking

To communicate effectively with pattern makers and manufacturers, mastering the terminology is non-negotiable. While the basics like Knife and Box pleats are staples, 2026 collections are seeing a resurgence of complex, machine-generated textures. Here are the 8 core types that dominate modern production:

Fancy/Machine Pleats:

Custom patterns created by specialized computer-controlled machines, capable of changing pleat direction or combining types (e.g., a box pleat that turns into a knife pleat).

Best for: High-end designer collections seeking a unique brand signature.

Knife Pleats:

The most common form where folds are pressed in one direction, overlapping each other.

Best for: Basic skirts, school uniforms, and side-seam details.

Box Pleats:

Two knife pleats turned away from each other, creating a flat, raised “box” on the right side.

Best for: Structural skirts that need waist volume without bulk.

Inverted Pleats:

Essentially a box pleat in reverse; two knife pleats folded toward each other to meet at the center.

Best for: Kick pleats in pencil skirts to add a hidden range of motion.

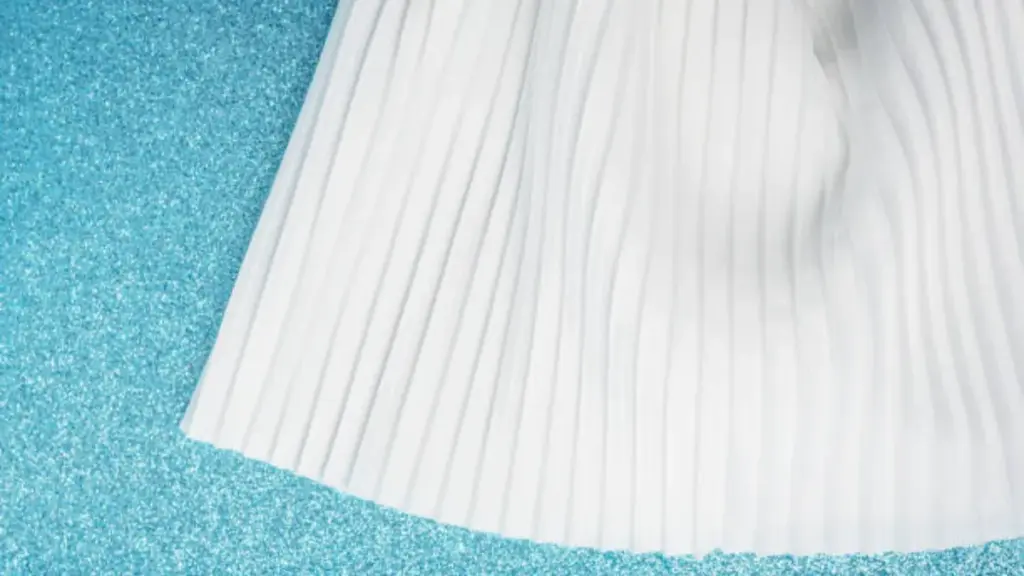

Accordion Pleats:

Narrow, even, and sharp-edged folds that resemble the bellows of an accordion.

Best for: Midi skirts and fluid dresses that need to expand dramatically with movement.

Sunray Pleats:

A variation of accordion pleating where the folds radiate from a central point, starting narrow at the waist and widening toward the hem.

Best for: Circle skirts (on the bias) to create a slimming, flared silhouette.

Crystal Pleats:

Extremely fine, sharp, and narrow pleats (usually 2mm-3mm) that are heat-set to create a crinkled texture.

Best for: Evening wear and formal gowns requiring rich surface texture.

Mushroom Pleats:

Similar to accordion pleats but with a softer, rounded tip rather than a sharp crease.

Best for: Flowing chiffon dresses where a romantic, less geometric look is desired.

The Science Behind the Fold: Best Fabrics for Permanent Pleating

One of the most common questions designers ask is: “How do I make the pleats stay sharp after washing?” The answer isn’t in the sewing—it’s in the molecular structure of the fiber.

Why “Thermoplastic” Matters

For a pleat to be truly permanent without chemical resins, the fabric must be thermoplastic. Synthetic fibers like Polyester, Nylon, and Acrylic fall into this category.urious hand-feel.

| Fiber Category | The Science (Thermoplasticity) | Pleating Outcome |

|---|---|---|

| Synthetic Fibers (Polyester, Nylon, Acrylic) |

Thermoplastic. These fibers soften at specific high temperatures and “lock” into the new folded shape upon cooling, essentially memorizing the structure. | Permanent & Crisp. The pleats remain sharp even after machine washing. This is the industry gold standard for durability. |

| Natural Fibers (Silk, Cotton, Linen) |

Non-Thermoplastic. These fibers do not set with heat alone. Humidity and moisture will naturally relax the fiber bonds back to their original flat state. | Temporary or Stiff. Requires harsh chemical resins or top-stitching to hold shape, which often ruins the soft hand-feel of the fabric. |

| High-Sim Poly (Hangzhou Garment Sourcing) |

Advanced Engineering. We source recycled synthetics and blends specifically designed to mimic the matte finish and breathability of natural silk. | The Best of Both. You get the luxury aesthetic of silk with the technical properties required for permanent industrial pleating. |

At Vêtements de Hangzhou, we source advanced “High-Simulation” Polyesters from the Guangzhou market. These fabrics offer the breathability and matte finish of natural silk or cotton but retain the thermoplastic properties required for crisp, permanent industrial pleating.

The Industrial Pleating Process

While a home sewer might use an iron and pins, mass production requires a process that blends engineering with craft. Understanding this workflow helps you plan your lead times and costs accurately.

Step 1: Pattern Calculation (The 3x Rule)

Pleating consumes significantly more fabric than flat garments. As a general industry rule, we calculate 3 times the width of the finished hip measurement. For example, a skirt with a 1-meter hem circumference requires approximately 3 meters of fabric before pleating. This calculation is crucial for your costing and fabric procurement.

Step 2: Kraft Paper Molds (The “Sandwich”)

The fabric is not pressed by a metal plate but is “sandwiched” between two layers of specialized, heavy-duty Kraft paper molds. These molds are pre-folded by machines into the specific pattern (Sunray, Accordion, etc.). The fabric must be carefully laid flat between the paper layers to prevent bubbling or twisting—a step that requires skilled manual labor.

[Insert Image: A worker placing fabric between two layers of pleated paper molds]

Step 3: Steam Autoclave Setting

Once rolled tightly, the paper-fabric sandwich is placed into a steam autoclave (an industrial pressure cooker). It is baked at temperatures often exceeding 200°C (392°F) for 1 to 2 hours. This heat resets the fiber memory. After removal, the rolls must cool completely before being opened to ensure the pleats set effectively.

Pro Tip: Why handmade samples often fail.

Designers often submit a hand-pressed sample made with a domestic iron. While it looks good in the studio, a domestic iron cannot reach the sustained, uniform heat and pressure of an autoclave. Consequently, the production bulk—which is heat-set industrially—may drape differently or feel stiffer than the sample. Always request a “production-method” swatch for approval.

How Hangzhou Garment Solves the “Small Order” Dilemma

Many emerging brands face a major roadblock: traditional factories often refuse small orders for pleated garments due to the complex, time-consuming nature of the pleating process. The setup time for molds and machinery makes small batches “unprofitable” for giant manufacturers.

Hangzhou Garment was established to solve this exact industry pain point. We specialize in serving wholesalers, boutique designers, and brand owners who need high-quality production without massive volume commitments.

The Partner You Need Among Women’s Wholesale Apparel Manufacturers

2026 Style Trending Applications of Pleats in Fashion

Looking ahead to 2026, pleats are evolving beyond simple schoolgirl skirts into complex, architectural statements. Designers are increasingly experimenting with asymmetrical pleating, where pleats vary in width or direction across the garment to create visual tension. Another rising trend is the use of metallic and sheer fabrics, where the pleating process enhances the play of light and shadow on the body.

- Asymmetrical Pleating: Instead of uniform widths, designers are mixing pleat sizes—alternating between wide box pleats and micro knife pleats on the same garment. This creates visual tension and a modern, deconstructed look.

- Metallic & Sheer Textures: “Liquid Metal” aesthetics are huge for 2026 party wear. Pleating metallic lamé or high-gloss satin enhances the play of light, making the garment look like moving water. Similarly, layering pleated sheer tulle over solids creates a ghosting 3D effect.

- Mixed Media (Hard vs. Soft): We are seeing a rise in pleats applied to non-traditional fabrics like faux leather (PU) and waxed denim. This juxtaposition of a rigid material with a fluid, folded structure creates a high-fashion, edgy silhouette that stands out in the market.

Conclusion

Creating the perfect pleated dress requires a delicate balance of artistic vision and manufacturing discipline. From selecting the right thermoplastic fabric to executing precise industrial heat-setting, every step impacts the final quality of the garment.

For brands looking to scale, the key is finding a partner who understands these nuances. With 16 years of experience, a supply chain rooted in Guangzhou, and a commitment to supporting small-to-medium orders, Hangzhou Garment is ready to be that partner.